QUESTIONS AND ANSWERS FOR EXISTING MANUFACTURERS

1. WHAT IF YOU HAVE A COMPLETED HEATING DEMI WATER FACILITY ?

POSSIBLE UPGRADE TO HWR CF TECHNOLOGY

- If you use demineralized water heating during the production process, we can probably offer you a modification and upgrade to COLD FUSION technology in order to avoid significant water heating costs. In the example of batch production of 2000 liters, this means that you will save a minimum of 60-80 kW of electricity per 2000 liters batch. Calculate the amount of savings on a daily, monthly or annual basis according to the capacity of your plant !

JUST A HWR CF MODULE

- We can also offer you the delivery of only the COLD FUSION module, which includes a hooper for Urea and tanks for production with COLD FUSION Technology. In case of this possibility, you must have ready demineralized water, electric power and a storage tank for the finished additive product. The result will be high-quality and reliable equipment, which with COLD FUSION technology consumes 80% less electricity, and creates a high-quality product that does not contain unwanted biuret and triuret.

2. WHAT IF YOU HAVE BAD DEMINERALIZED WATER ?

JUST A HWR DEMI WATER PRODUCTION MODULE

- In case you have bad demineralized water, or you use water from a well, there is an option of just buying a module for the production of demineralized water. In the case of using feed water from a well, our module will UV sterilize it.

3. WHAT IF I HAVE INACCURATE CHARGING OF THE FINISHED PRODUCT IN IBC CONTAINERS?

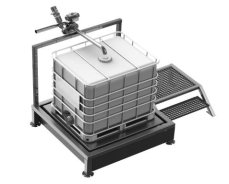

JUST A HWR IBC CHARGER

- In the event that you fill IBC containers with imprecise devices and thereby cause harm to yourself or your customer, it is possible to purchase only the HWR CF Charger Module for precise filling. It is possible to choose one or two chargers, each of which has 4 measuring cells for precise charging and automatic valves for fast and slow charging. After installation, our module for precise charging can be tested and certified by an authorized company in your country.

4. WHAT IF YOU RECEIVE DIRTY IBC CONTAINERS?

JUST A HWR IBC WASHER

- To make sure that the IBC containers are clean and that their dirt will not contaminate the finished additive product, they must be machine washed. It is not effective enough to wash them with a mini wash. It is possible for us to offer you the HWR CF module for washing IBC containers, whose washing head enters the container and washes the container in a 360° radius under a pressure of 140 bar. In order for the container to be adequately washed, our washing machine has a 5-minute washing program, where half of the time it uses ordinary water, and then rinses it with demineralized water. In case of interest in purchasing only this module, it is necessary to ensure the connection of city and demineralized water.

5. WHAT IF YOU HAVE DIFFICULTIES WITH BLOCKED UREEA?

JUST A HWR CRUSHER

- If you have problems with blocked or glued Urea during production, we can offer you an HWR crusher that has a stand for IBC bags, a 2 m3 hopper and a special V crusher. It is necessary to cut the bag of Urea and lower it into the hopper, where our crusher with special rollers-knives breaks the lumps without damaging the urea structure itself.

6. WHAT IF ALGAE APPEARS IN THE FINISHED PRODUCT?

- In plants that do not have good water quality or use uncontrolled well water, there is a possibility of algae formation after a certain time. First of all, it is necessary to provide demineralized water of appropriate quality, and it is necessary to install UV sterilization at the water inlet, and UV sterilization of the finished product is also recommended due to the possible contamination of Urea itself. HWR CF modules have both UV sterilizers to ensure that there is no algae formation in the finished product after long storage.

7. WHAT IF YOU HAVE AN UNWANTED BIURET AND TRIURET IN THE PRODUCT ?

- Unwanted biuret and triuret, which are actually the biggest enemies of the SCR system, come from Urea that is not of satisfactory quality. During classic production processes, an attempt is made to melt them by mixing and heating, but this is a method that is not completely successful. Since the HWR CF technology uses a cold production process, the biuret and triuret particles remain unmelted, which makes it easier to separate them by mechanical filtration, which is exactly what the HWR CF system does.

For any other technical questions, feel free to contact us via the contact form.